The AnitaTM Mox processes - MBBR (Moving Bed Biofilm Reactor) is single-stage deammonification technologie where greater than 90% of ammonia and 75-85% of total nitrogen can be removed. The processes accomplish this removal without the addition of an external carbon source and with considerably less energy in comparison to conventional nitrification-denitrification.

The principle

The Anita™ Mox process is performed in 2 steps: aerobic nitritation and anoxic ammonia oxidation performed by anammox bacteria.

The two steps are taking place in a one-stage biofilm process in different layers of the biofilm: nitritation (aerobic) in the outer layer of the biofilm, anammox (anoxic) in the inner layer.

This can be achieved within a single MBBR reactor. Specific conditions (pH, temperature, oxygen level) are maintained within the reactor to allow the process specific bacteria to grow as a biofilm on AnoxKaldnes® carrier media. All the benefits of proven MBBR technology are applicable to Anita™ Mox including retention of critical biomass, a stable and robust process and a small footprint.

Customer benefits- over conventional ammonia removal

- No carbon source needed

- Compact process

- Almost 60% oxygen savings

- Reduced sludge production

- Robust process

- Stable process

- Lower CO2 emissions

Reject Water Treatment

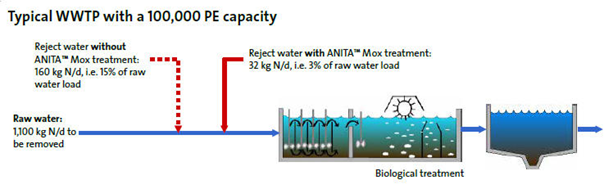

High ammonia concentration with low COD concentration are typical characteristics of the reject water coming from centrifugation of the digested sludge. Usually sent back to the main wastewater flow, the treatment of this ammonia load through conventional nitrification/denitrification can be quite cost-intensive.

The use of the Anita™ Mox process on reject water can reduce dramatically the nitrogen load on the existing biological treatment line. It is also a way to treat a part of the nitrogen at a low energy and chemicals cost. In addition, it allows a reduction of the nitrogen load on the main treatment line and therefore is a solution to upgrade an overloaded existing wastewater treatment plant at a low cost.

A Key Element : The Plastic Carriers

A key element of the MBBR technology is the AnoxKaldnes carriers. They are designed to provide a large protected surface area for the biofilm and optimal conditions for biological activity when suspended in water.

Three different types of carriers are best suited for use in the ANITA™ Mox process:

- K3, with a protected surface area of 500 m2/m3

- K5, with a protected surface of 800 m2/m3

- BiofilmChip™ M, with a protected surface area of 1,200 m2/m3

These carriers of different shapes and sizes provide flexibility to use the most suitable type depending on reject water characteristics and available volumes.

The Biofarm Concept

for a quick start-up of new ANITA™ Mox plants

Specific ANITA™ Mox plants will be used as Biofarms where pre-seeded carriers can be harvested to seed the start-up of new ANITA™ Mox plants around the world. A small percentage of carriers used as seed will dramatically reduce the start-up phase from 9-19 months to 2-5 months.